PRECISION MACHINING OF TURNED COMPONENTS

At JP Swiss Mfg. we specialize in screw machined products, precision turned and milled parts machined from bar stock to your specifications and tolerances. Our machines can accommodate smaller quantity runs (5-100 pieces) all the way to high volume production (100,000+ pieces).

We strive to make our customer’s experience the best it can be providing your parts on time and on spec at competitive pricing. We are always just an email or phone call away ready to answer any questions.

To learn more about our capabilities!

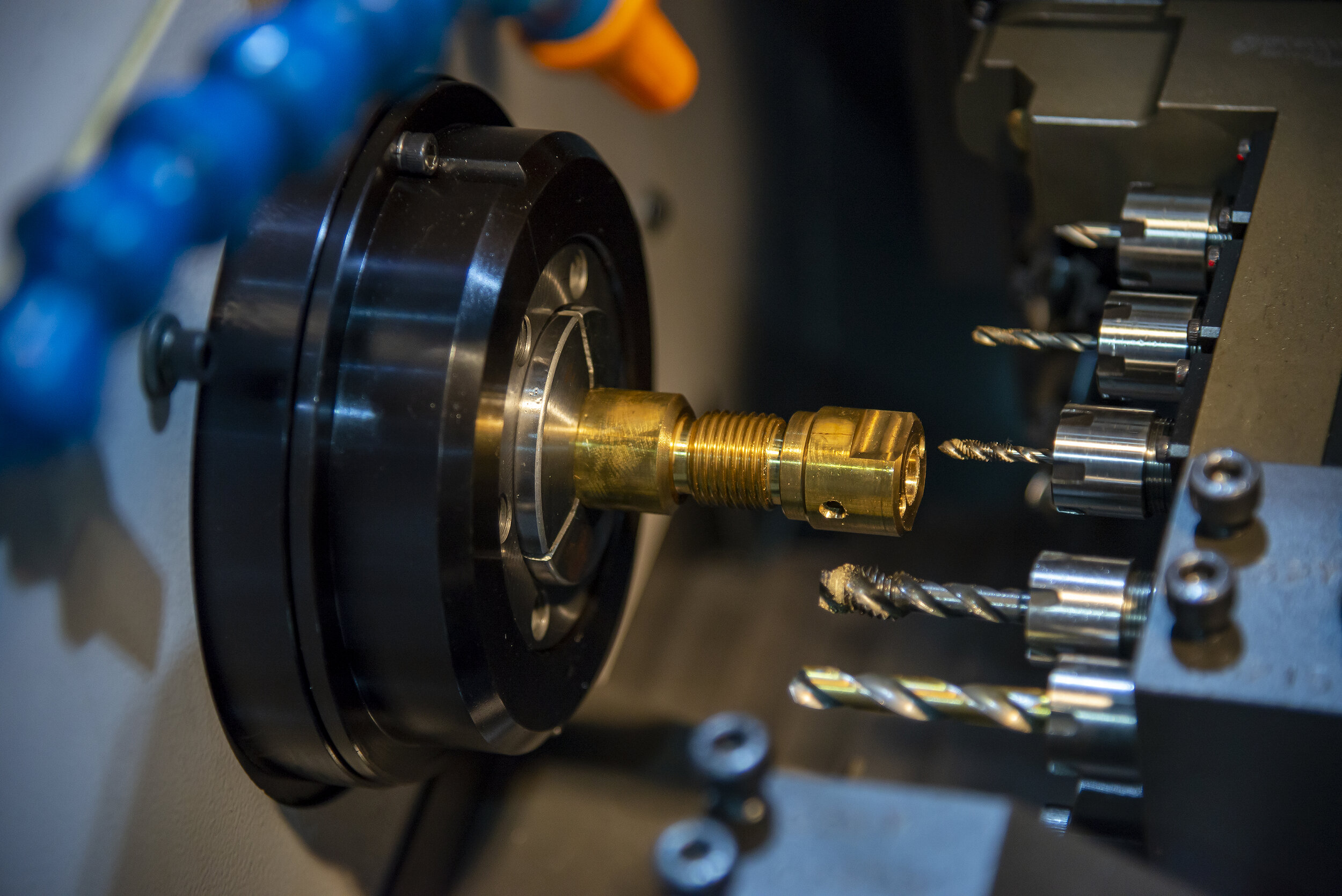

What is a CNC Screw Machine?

At JP Swiss we specialize in Swiss machining which is production manufacturing of turned components ran automatically.

Today’s modern screw machines primarily consist of Swiss style automatic lathes and are well equipped with live tooling and sub spindles making them capable of machining complex parts featuring milled slots, flats, cross holes, cross threads, off center holes and threads, etc. Modern CNC Swiss machines run these complex parts extremely fast with very consistent and tight tolerances as low as 0.0001” of an inch deviation.

Our goal is to continue improving our processes and capabilities to better help our customers receive excellent parts on spec, on time, and at competitive prices.

If you have any questions, please reach out: john@jpswiss.com